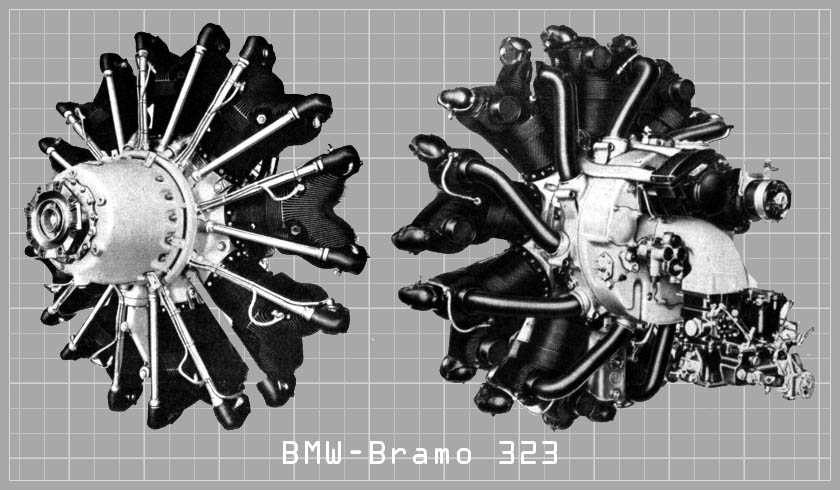

BMW-Bramo 323

Development of the 323 was the end result of a series of modifications to the original Jupiter design, which Siemens licensed in 1929. The first modifications produced the Sh.20 and Sh.21. The design was then bored out to produce the 950 hp (708 kW) Sh.22 in 1930. Like the Jupiter, the Sh.22 featured a rather "old" looking arrangement with rather prominent valve pushrods on the front of the engine. In the mid-1930s the Reich Air Ministry (RLM) altered the way in which engines were assigned code names, and Bramo was given the 300-block of numbers. Therefore, the Sh.14 and Sh.22 became the 314 and 322, respectively. The 322 never matured and remained unreliable. The team continued work on the basic design, adding fuel injection and a new supercharger. The resulting Bramo 323 was just under 27 l in displacement, and produced 900 PS at 2,500 rpm for takeoff, improving slightly to 1,000 PS at 3,100 m (10,200 ft). The reduced power at sea level was inevitable for engines with single-speed, mechanically-driven superchargers when they were regulated to a constant maximum boost pressure below their critical altitude. The Fafnir powered a number of German prewar designs, including the Focke-Wulf Fw 200, Henschel Hs 126, Dornier Do 24 and Dornier Do 17, as well as the Focke Achgelis Fa 223 Drache helicopter. Its fairly poor fuel economy kept it from more widespread use, and most designs chose the similar BMW 132 instead, whose specific fuel consumption varied between 220 and 240 g/(kW•h) depending on model, whereas the early versions of the Fafnir got about 255 g/(kW•h), a poor figure for the era. The C/Ds, where the supercharger used less power, improved this to 230 g/(kW•h), but were only useful at lower altitudes. BMW bought Bramo in 1939 and continued production to supply the small number of designs that already used it, notably the Do 17. The naming at this point becomes somewhat confusing, with BMW, Bramo and Fafnir being used almost interchangeably depending on the source. 5,500 were produced before the lines were shut down in 1944. The original 323 design was produced in A and B models, differing in the direction they turned. The engines were intended to be installed in A/B pairs, thereby eliminating engine torque across a twin-engine aircraft. The similar C and D models featured a lower supercharger gearing for better performance at lower altitudes, improving takeoff power to 1,000 PS, but reducing the critical altitude. The final versions, P, R and T, featured a two-speed supercharger for better all-around performance. This allowed it to generate 1,000 PS at sea level as in the C/D models, but improved altitude performance considerably, delivering 940 PS at 4,000 m (13,000 ft). The R-2 subtype added MW 50 water-methanol injection for added low-altitude performance, boosting power to 1,200 PS at 2,600 rpm. Variants

- 323A Right hand rotation.

- 323B Same as A but left hand rotation.

- 323C Lower powered supercharge 1,000 PS (986 hp; 735 kW) for take-off. Right hand rotation.

- 323D same as C but left hand rotation.

- 323J Right hand rotation

- 323M Right hand rotation

- 323P 2-speed supercharger:- 940 PS (927 hp; 691 kW) at 4,000 m (13,000 ft)

- 323R No information available

- 323R-2 MW 50 water-methanol injection 1,200 PS (1,184 hp; 883 kW) at 2,600 rpm

Manufacturer: BMW

Developed: 1936

Type: 9-cylinder supercharged air-cooled radial engine

Number Built: ~5,500 Dimensions:

Bore: 154 mm (6.06 in)

Stroke: 160 mm (6.30 in)

Displacement: 26.82 litres (1,636.8 cubic inches)

Length: 1,420 mm (55.9 in)

Diameter: 1,388 mm (54.6 in)

Dry weight: 550 kg (1,210 lb)

Components:

Valvetrain: Pushrod-actuated overhead valve

Supercharger: Gear-driven

Fuel system: Fuel injection

Fuel type: 87 Octane petrol

Cooling system: Air-cooled Power output:

- 1,000 PS (986 hp; 735 kW) at 2,800 rpm (max) at 3,100 m (10,171 ft)

- 900 PS (888 hp; 662 kW) for takeoff at 2,500 rpm (1 minute) at sea level

- 730 PS (720 hp; 537 kW) at 2,350 rpm (5 minutes) at sea level

- 660 PS (651 hp; 485 kW) at 2,250 rpm (30 minutes) at sea level

- 585 PS (577 hp; 430 kW) at 2,100 rpm (max. continuous) at sea level

- 515 PS (508 hp; 379 kW) at 2,000 rpm (cruise) at sea level

Compression ratio: 6.4:1

Specific fuel consumption: 0.348 kg/PS/h (0.778 lb/hp/h; 0.473 kg/kW/h) at max continuous

B.M.E.P.: 9.37 atm (9.49 bar; 137.7 psi)

Power-to-weight ratio: 1.33 PS/kg (0.60 hp/lb; 0.98 kW/kg)

Design & Structure:

FUEL INJECTION – Maihak duplex feed pump draws fuel from supply tank through lines and combined cocks and filters, the deliveries combining to pass through de-aerator and thence to Bosch injection pump. This nine-cylinder pump is similar to that fitted to BMW 132 engine. Quantity-Control racks moved by oil servo-motor controlled by boost pressure. Changes in exhaust back pressure and (unlike BMW) in boost air temperature have no controlling effect. Metered fuel fed through soft iron pipes to Bosch injection valves in &ont of cylinder-heads. Askania automatic boost-pressure control unit as used on BMW 132 engine.

LUBRICATION - Scavenge and pressure pumps mounted as single unit on auxiliary gear box. Pressure oil passes into ducts in wall of auxiliary gear box and to edge-type filter provided with external cleaning handle and thence through non-return valve and cored passage in lower part of supercharger casing to all components. Drainage from all parts of engine to magnesium-alloy sump on underside of crankcase, scavenge oil being drawn through wire gauze filter in bottom of sump.

IGNITION - Dual Bosch magneto mounted on upper part of auxiliary gear box and provided with draught of cooling air through a duct. Two Siemens plugs per cylinder. Conventional ignition harness.

AUXILIARY DRIVES - Auxiliary gear box is a magnesium-alloy casting mounted on rear of supercharger casing. Drive taken from gear wheel formed on supercharger spring drive to gear of same size on layshaft, after end of which is machined with claws for inertia starter. Train of gears drive magneto, tachometer, oil pumps, vacuum pump, petrol pump, injection pump and generator.

COWLING AND BAFFLES - Three baffles of aluminum-alloy sheet to each cylinder, two side pieces and a head-piece, all closely fitting to the fin tips. Side pieces extend from push-rod tubes in front to within a few inches of center line at back of cylinders. Head piece fixed to rocker boxes and extends outwards to ring running round engine and itself in contact with external cowling. Inter-cylinder spaces filled by flat pieces extending to ring and through these are air intakes for magneto cooling, breather (forward side of supercharger impeller) port and starboard air heaters, generator cooling and breather from sump. There is no internal cowling behind engine except a deflector for warm air intake of supercharger. Large diameter nose cowling of aerofoil section attached by struts to reduction gear casing and crankcase. Remainder of cowling, extending to rear of oil cooler, parallel and hinged at top to give access to engine. No means of controlling air flow provided.

MOUNTING - Lugs on supercharger casing pick up nine points on mounting ring, through rubber bushes and bolts, which forms part of triangulated welded steel-tube structure terminating in four spherical joints for attachment to the airframe. A twin steel wire cable is wound round various parts of the mounting and attached by links to brackets high up on the airframe to prevent the engine falling out should the bearer break.

Used in:Wikipedia

Gunston, Bill (2006). World Encyclopedia of Aero Engines: From the Pioneers to the Present Day (5th ed.). Stroud, UK: Sutton. ISBN 0-7509-4479-X.